Cold Box Resin Composition:

Cold box resin consists of two parts:

Cold box resin (component I) and Core box resin (Component II)

Component I:A special phenolic resin soluble in solvent, a light yellow to brown liquid;

Component II:A polyisocyanate dissolved in a solvent, a brown liquid.

Instructions:

1. The moisture content of raw sand is controlled at ≤0.2%, the mud content is controlled at ≤0.26%, the humidity is 16-38°C, and the mesh size of the sand mold is: 50-100 mesh.

2. The amount of resin added is generally between 1.0-2.0 (proportion of sand weight).

3. The ratio of mixed sand and resin: generally controlled at 50:50 (component I can also be adjusted to 0.55 kg and component II to 0.45 kg according to the casting. The more component I is added, the higher the initial strength will be).

4. Sand mixing time: Intermittent sand mixer, 2-3 minutes after adding resin.

5. The product is cured with triethylamine, and the amine blowing time depends on the size and shape of the sand core.

Range of application:

Cold box resins have excellent use on gray iron, ductile iron, copper, aluminum, magnesium and steel castings.

It has been widely developed and used in cylinder blocks, cylinder heads, water jackets, exhaust pipes, crankshafts and other products of automobiles, tractors and internal combustion engines. In recent years, it has been widely used in brake pads, cast pipes, machine tools, water pumps, motors and so on. There are also a large number of applications in the shell and other industries.

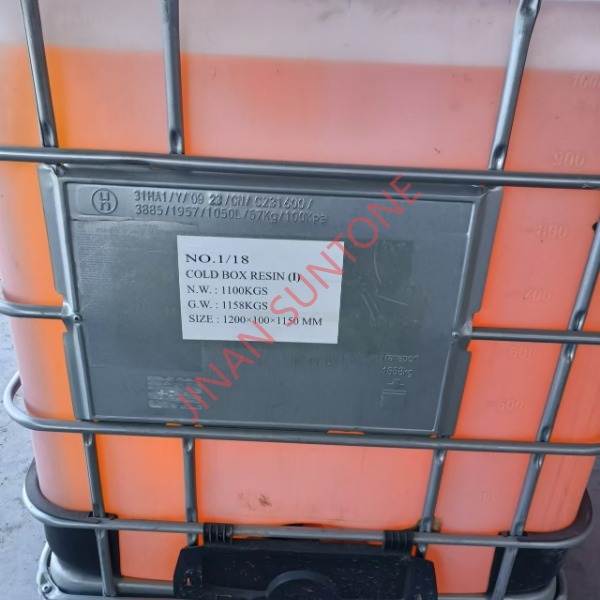

Packaging: Iron drums (net weight 220kg/Barrel)+Pallet;

IBC (net weight 1000kgs/IBC)

Storage:The resin should be stored between 10-35°C to avoid contact with water, fire, etc.

Shelf life:6 Months.