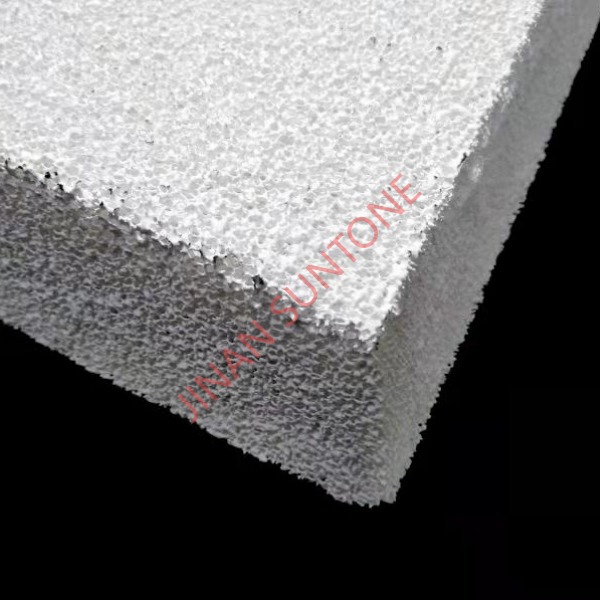

1. Fully automated production, multi-test&calibration, high dimensional accuracy, and high fit with filter box can prevent floatation and leakage of molten aluminum.

2. High porosity, high filtration efficiency, easy replacement, low cost, and strong adaptability.

3. The filter is adopted the adsorption principle, which can effectively remove large inclusions in molten aluminum and absorb small-sized inclusions.

Usage:

1.Check and clean the sundries on the surface of the filter box to keep the filter box clean and free from damage.

2.Put foam filter into filter box gently, and press the surrounding sealing gasket tightly to prevent molten aluminum from floating or leaking.

3.Preheat filter box and foam filter evenly to make sure the temperature as close as molten aluminum. The preheating temperature cannot lower than 550 ℃ . Preheating can remove adsorbed water to help open thepore in a short time and prevent partial hole blockage due to thermal expansion and cold contraction. Electric or gas heating can be used for preheating, and heating time shall not be less than 30 minutes.

4.Pay attention to the change of the pressure drop during casting, and maintain the control of normal demand of molten aluminum.

5.Knocking and vibrating the foam filter is prohibit during the normal filtration process. Meanwhile, the launder should be full of molten aluminum to avoid the fluctuation of the molten aluminum.

6.Take out CFF and clean the filter box in time after finishing the process.

Storage:

Store in a ventilate and dry environment to prevent moisture, and do not place object.

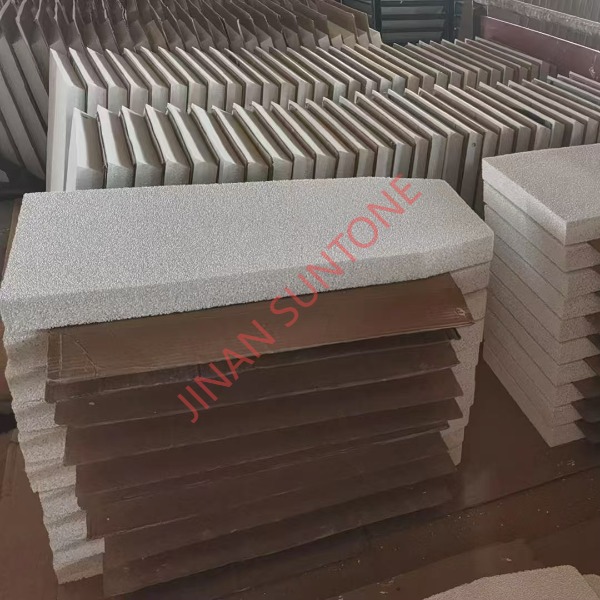

Packaging:

The sealing gasket of the CFF classifies fiber cotton, and expanded cotton. The CFF is packed in an individual carton. The information of the inner carton label includes model, size, weight, production date, batch number, porosity,compression strength, and ppi. Five pieces are in one carton, packed in wooden pallets.